Leaders in Wheel Blasting

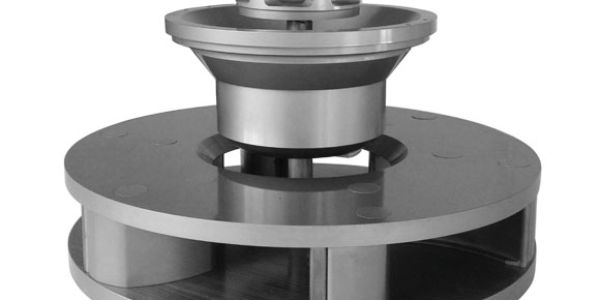

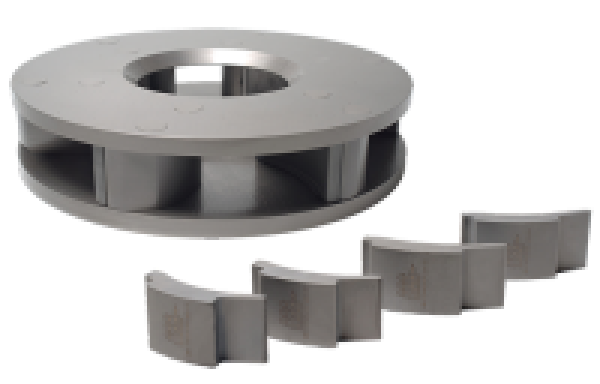

Patented GN Wheel®

Prior to post-processing, metal castings are cleaned by means of wheel blasting. This process releases forces which cause peak loads on the blasting wheel of the blasting machine. Straaltechniek developed the GN Wheel®, a robust blasting wheel with wear-resistant blades having the longest service life on earth.

Wheel blasting in foundries & forging

In heavy industries such as an iron foundry or forge blasting machines have a tough time. While blasting metal castings or forgings, enormous forces are released; not only by the blasting media itself, but also vented moulding sand particles have a devastating effect on the blades of the blasting wheel. This results in high costs of replacing spare parts, production losses and maintenance down time.

Longest service life on the market

Straaltechniek developed a new wheel blasting turbine with the longest service life on the market. The innovative design of this patented GN Wheel® provides a service life extension of a factor 10 and an efficiency increase of at least 70%!

Even with the use of sharp-edged grit, such as GL, the GN Wheel® is a winner. For instance, our customers with GN® turbines are winners as far as lower costs and longer ‘up-times’ of the machine are concerned.

High efficiency and improved blasting media flow

The GN Wheel® is fitted with forward curved, hard metal blades and an ingenious blade support system. The innovative design of the GN Wheel® ensures an optimised blasting media flow of up to a factor of 7 in comparison with turbines now on the market. Moreover, an energy saving of 5% is realised. An optimised blasting media flow also ensures a service life extension of the side plates of up to a factor of 3.

Extend Lifespan

Increased Efficiency

Quality Standards

ISO certified and member of a number of branch organisations.

A range of related products

Underneath you’ll find a selection of related products to the energy industry. For our complete delivery program, you can visit the equipment pages or contact us directly.